Remotely Monitoring Conductivity in Treated Water

Keeping commercial and industrial operations running smoothly relies on a tremendous amount of data. Sensors monitoring various process parameters capture this data which is then sent to a display, controller, or another device where it can be monitored, analyzed, and used to increase efficiency, ensure quality control, and improve workplace safety.

Accessing and keeping track of this data can be difficult and time-consuming especially when the system includes a large number of sensors, sensors that are spread far apart, or sensors placed in remote locations.

Fortunately, advances in wireless technology like the industrial internet of things (IIoT) make it easier than ever to gather, monitor, and analyze data from remote sensors using Ethernet sensor hubs connected to a cell network modem. There are a number of companies that are doing exciting work that demonstrates the enormous potential of remote monitoring solutions using IIoT.

One such company is our friends at Valarm who recently purchased sensors from us that they could use in a project they were involved with.

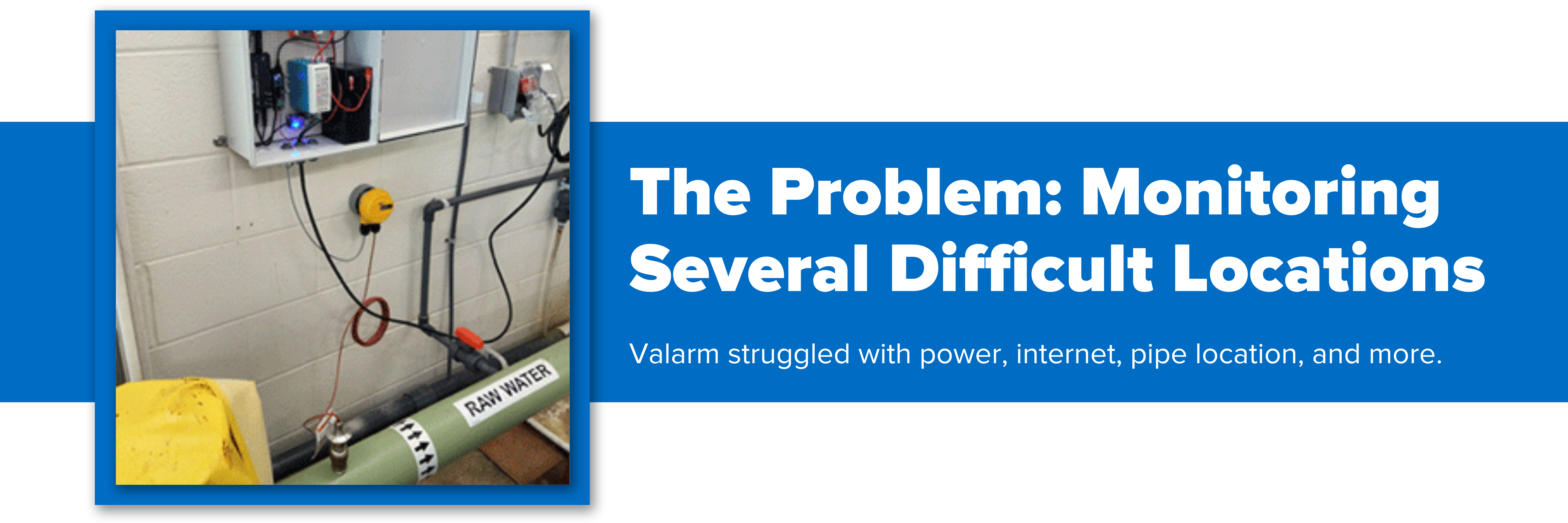

The Problem: Monitoring Several Difficult Locations

Valarm designs and builds critical asset monitoring systems for customers across a range of industries using their flexible, open Tools.Valarm.net / Valarm Tools Cloud platform. This system is highly flexible and, as long as there’s a cellular signal available, suitable for any location. The power required by the sensors, Ethernet hub, modem, and any other equipment can be provided by standard mains or by solar panels with battery back-up for off-grid installations.

Valarm designs and builds critical asset monitoring systems for customers across a range of industries using their flexible, open Tools.Valarm.net / Valarm Tools Cloud platform. This system is highly flexible and, as long as there’s a cellular signal available, suitable for any location. The power required by the sensors, Ethernet hub, modem, and any other equipment can be provided by standard mains or by solar panels with battery back-up for off-grid installations.

For this particular application, Valarm worked with officials in Tioga County, Pennsylvania to design a system to monitor water quality throughout several locations including water treatment plants, universities, boroughs, townships, and additional communities. Valarm provided the sensor hubs and power supplies but they required a number of conductivity sensors suitable for the demands of the application.

Valarm faced some challenges with this application, specifically with regards to power, internet availability, pipe location, and sensor attachment. They designed the system using the 4-20mA output standard since it is easy to deploy, reliable, durable, accurate, and offers increased immunity to electrical interference and signal loss over long cable runs. Additionally, since the sensors will contact treated water they had to meet sanitary specifications, including USP requirements, and had to have NIST traceability certification.

The Solution: GF Signet Sensors

We worked with Valarm to find conductivity sensors that met the application specifications for durability, output, sanitary requirements, and NIST traceability and determined GF Signet 2821 conductivity sensors paired with GF Signet 2850 sensor electronics would be the ideal solution.

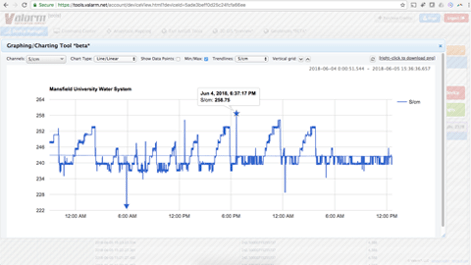

The system has since been installed and automatically uploads conductivity readings to Tools.Valarm.net providing real-time access to the data captured by many sensors across a wide distance, some in remote locations, and does so affordably, reliably, and accurately. The system, once set up, is simple to operate and adaptable to changing needs. It is a great example of the power of the IIoT and the future of data collection. It is also, by all accounts, running flawlessly.

Still Need Help? Call an Engineer Today

If this post still leaves you wondering what type of industrial instrumentation would work best for your application, our engineers would be happy to help you. Give them a call at 1-800-884-4967. Or, you can shop for a wide range of industrial instrumentation from top brands and even configure your product online. We offer free lifetime tech support with every product sold.